Beacon Machine Manufacturing Co.,ltd

Diagnosis and Treatment of Common Diesel Turbocharger Faults | Beacon Diesel

Diagnosis and Treatment of Common Faults in Turbocharging Systems

The high-temperature and high-speed exhaust gas discharged from the diesel engine cylinder enters the turbine of the turbocharger, driving the turbine rotor to rotate. The turbine then drives the compressor impeller on the same shaft to rotate, compressing the sucked-in air, increasing the pressure, and sending it into the intake pipe and then into the cylinder. This achieves the effect of increasing the air density in the cylinder, allowing more fuel to burn completely, thereby improving the power of the diesel engine, reducing fuel consumption. Due to the improvement of combustion conditions, it not only reduces the emission of harmful substances in the exhaust gas but also reduces the noise of the diesel engine operation.

The turbocharger is a power machine that rotates at ultra-high speeds in a high-temperature environment. Its working speed at full load is generally 80,000~120,000 r/min, and the maximum can reach over 200,000 r/min. Such high-speed rotating machinery is often damaged due to improper installation and use, leading to the diesel engine's inability to operate normally.

Regardless of whether the turbocharger in use is domestic or imported, its service life generally fails to reach the expected service years. More than 90% of the root causes are improper installation and use. Severe overloading or unauthorized modification of fuel injection characteristics are the main factors affecting the service life of the turbocharger. Common faults of the turbocharging system are as follows.

8.1.1 Insufficient Intake

Insufficient intake refers to the lack of air intake caused by blockage in certain parts outside the compressor inlet of the turbocharger. The main reasons are:

-

Air filter element clogging. Air filters include paper filter elements and safety (felt) filter elements. Diesel engines working in harsh environments use oil bath air filters. Regardless of the type of air filter, the filter element must be maintained, cleaned, or replaced after a period of use. If the air filter element is not maintained, cleaned, or replaced for a long time, the filter element may lose permeability due to excessive dust adhesion.

-

Blockage in the intake pipe. In the intake pipeline before the compressor, there are generally transition rubber hoses. If these rubber hoses are folded, flattened due to external force, or the inner skin falls off, it can lead to insufficient intake faults.

(1) Fault Phenomenon

After insufficient intake occurs in the negative pressure section, the diesel engine will show symptoms such as abnormal smoke exhaust (black smoke) and insufficient power. Phenomena such as excessive temperature and the turbocharger turbine casing turning red may also occur.

(2) Fault Diagnosis

When the air intake before the compressor is not smooth, check comprehensively whether the above parts have problems, and replace the air filter or the transition rubber hose of the intake pipe. Specific diagnosis steps and requirements can be found in the relevant sections later in this chapter.

(3) Fault Handling

If inspection reveals that the air filter element is dirty or there is blockage in the intake pipeline, the air filter element and damaged related pipes and seals should be replaced.

(4) Fault Example: Overheating Caused by Insufficient Intake

-

① Fault Phenomenon: An imported scraper, powered by a model 3208 diesel engine. During construction, it accidentally tipped to the right side. After being hoisted up, the damage seemed minor. After simple maintenance, the operation continued, but soon symptoms of excessive coolant temperature, frequent alarms, and insufficient scraper power appeared.

-

② Fault Diagnosis: The air filter equipped with this machine has a single-stage dry structure with two large paper filter elements inside. The filter element was soaked by the engine oil flowing out of the diesel engine when the equipment tipped over. At that time, there were no spare parts to replace at the construction site, so the filter element was just washed and used continuously. Before long, the above fault phenomenon appeared. Therefore, it was suspected that the above fault phenomenon was caused by dirty air filtration. After removing the air filter element and running the diesel engine for a short time, the fault phenomenon did not reappear, confirming that the fault was indeed caused by the air filter element.

-

③ Fault Cause: This machine is a turbocharged diesel engine with a large displacement requiring a large amount of air intake. After the filter element was soaked by engine oil, it was quickly clogged by oil sludge and dust. This caused a drastic reduction in the air intake volume in the cylinder. The diesel fuel could not burn fully and continued to burn later (continuous burning in the exhaust pipe), which not only reduced power but also caused the engine temperature to rise.

-

④ Troubleshooting: After replacing the air filter element, the engine temperature returned to normal, the alarm light went out, and the fault phenomenon disappeared.

Warm Reminder: Difficult starting (or inability to start), insufficient power, and abnormal smoke exhaust caused by dirty air filter elements and blocked intake pipes are not uncommon. Therefore, when such faults occur in the diesel engine, if the cause is looked for in other parts but the fault cannot be eliminated, it may be necessary to check the air filter element and the entire intake system. Do not always assume that a new air filter assembly definitely has no problems; sometimes newly replaced filter elements may also have poor flow conditions.

8.1.2 Compressor Surge

When the turbocharger is working, if the air flow of the compressor is reduced to a certain extent, the airflow of the compressor will oscillate violently, causing blade vibration, and accompanied by abnormal noise, and the boost pressure will drop significantly. This phenomenon is called compressor surge. Its causes are as follows:

(1) Pressure Pulsation in Intake Pipe

Pressure fluctuation in the diesel engine intake pipe has a great impact on surge, especially for 6~8 cylinder diesel engines, where pressure fluctuation is relatively large. Since the frequency of intake pipe pulsation in diesel engines is low and the amplitude is large, surge is prone to occur.

-

Fault Handling: Install an air stabilizing box at the compressor inlet to reduce pressure pulsation; appropriately increase the intake pipe volume to reduce the pulsation amplitude; V-type 8-cylinder diesel engines can connect the left and right intake pipes with a thick pipe.

(2) Individual Cylinder Misfire

When two sets of turbochargers (assuming each connects to 3 cylinders) share one exhaust pipe, if one cylinder in one group misfires, the turbocharger of that group will surge. This is because after one cylinder misfires, the exhaust energy decreases, the turbine speed decreases, while the pressure of the intake pipe is still maintained by the other group of turbochargers which is operating normally. At this time, the compressor causes surge due to insufficient power absorbed by the turbine.

-

Fault Handling: Check the working condition of each cylinder of the diesel engine (methods such as high-pressure oil pipe pulse method and exhaust manifold temperature detection can be used), find the cylinder that is not firing, and repair (or replace) the fuel injector of that cylinder or other damaged parts as appropriate.

(3) Changes in Operating Load

If the throttle needs to be retracted quickly when shifting gears, the rotor of the turbocharger continues to rotate at a relatively high speed due to inertia. The gas pumped out by the compressor has nowhere to go, and the intake resistance is high, causing surge.

-

Fault Handling: Adding an intake relief valve (blow-off valve) can prevent surge and improve the service life of the turbocharger.

(4) Carbon Buildup in Turbocharger Passages

Severe carbon deposits or dirt accumulation in the compressor air passage or turbocharger turbine gas passage increase the passage resistance, which will cause compressor surge.

-

Fault Handling: Check and clean the relevant passages of the turbocharger, dredge all pipes of the intake and exhaust system; avoiding blockage of relevant passages is crucial for preventing turbocharger surge.

Warm Reminder: When a turbocharged diesel engine is designed, the matching of the turbocharger and the diesel engine is carefully calculated. Therefore, the probability of surge in original supporting products is relatively small. However, if the technical parameters of the replaced turbocharger differ greatly from the original product during maintenance, or if a naturally aspirated diesel engine is modified into a turbocharged diesel engine by oneself, the probability of surge occurring during use is much greater due to improper matching. Therefore, for the maintenance of the turbocharger, especially the replacement of the assembly, special attention should be paid to technical parameter matching.

8.1.3 Insufficient Boost Pressure

When the boost pressure drops, the air volume of the diesel engine decreases, power drops, fuel consumption increases, and exhaust temperature rises. Therefore, if the pressure drop is found to exceed 10%, stop and check. The main reasons for the decrease in boost pressure are:

(1) Air Filter Factors

The air filter element is full of dust causing blockage, or the intake pipe has blockage, the rubber hose is kinked or deformed, etc., increasing the intake resistance, increasing the intake suction loss of the compressor, leading to a drop in pressure.

-

Fault Handling: At this time, clean or replace the air filter element and check whether the relevant pipelines of the entire intake system are kinked, folded, or flattened.

(2) Dirty Compressor Passage

Due to the poor dust removal effect of the air filter, dust and engine oil adhere to the impeller of the turbocharger and the passage of the diffuser, increasing airflow resistance, and reducing compressor efficiency and boost pressure.

-

Fault Handling: To prevent and avoid this phenomenon, in addition to maintaining or improving the filtering effect of the air filter, the turbocharger compressor should be dismantled and washed regularly.

(3) Turbine Carbon Deposit

Due to poor combustion of the diesel engine and oil leakage due to failure of the turbocharger seal, carbon accumulates on the turbine blades, and between the rotating shaft and the seal ring, increasing the rotational resistance of the rotor, making the diesel engine difficult to start and poor in acceleration.

-

Fault Handling: Regularly maintain the turbocharger and clean the turbine of the turbocharger to avoid diesel engine oil burning faults as much as possible.

(4) Air Leakage

Leakage in the exhaust manifold or pulse pipe will reduce the turbine speed, causing the boost pressure to drop. In addition, leakage in the intake pipe or intercooler blockage will also cause the boost pressure to drop.

-

Fault Handling: At this time, pay attention to observing and listening for air leakage sounds or other abnormal phenomena; check carefully the exhaust pipe before the turbine and the intake piping system after the compressor.

(5) Regulation Device Failure

The boost pressure control valve (wastegate) fails due to excessively high temperature. The air release valve is not closed tightly due to carbon deposits, leading to regulation failure. When the boost pressure is low, a large amount of exhaust gas is released, causing the boost pressure to drop.

-

Fault Handling: Perform corresponding repairs on the turbocharger pressure regulating valve.

(6) Poor Exhaust

Poor exhaust from the turbine increases exhaust resistance, the expansion of gas in the turbine is inhibited to a certain extent, causing the turbine efficiency to decrease, the turbocharger speed to decrease, and the boost pressure to decrease. The reason is deformation of the exhaust pipe or blockage of the exhaust silencer.

-

Fault Handling: Check and dredge the exhaust system, focusing on checking whether the exhaust silencer, particulate filter, and catalytic converter and other exhaust after-treatment devices are blocked.

(7) Low Turbocharger Speed

If the connection between the turbocharger and the diesel engine (including intake and exhaust connections) leaks, or the turbocharger rotor is poorly lubricated, it may lead to insufficient turbocharger speed and lower boost pressure.

-

Fault Diagnosis: Check whether the connection between the turbocharger and the exhaust pipe leaks air, paying special attention to whether the joint between the pulse converter (pipe) and the turbine casing is sealed tightly without leakage. Check whether there is leakage or blockage in the piping from the turbocharger compressor outlet to the intake pipe, and pay special attention to whether the intercooler is blocked or has leakage.

Besides this, special attention should be paid to the oil pressure of the turbocharged diesel engine. If the oil pressure is too low, the turbocharger rotor will not get good lubrication, the turbocharger speed will drop, eventually leading to a drop in boost pressure.

-

Fault Handling: Perform repairs based on the diagnosis and inspection results.

(8) Turbocharger Mechanical Damage

Main reasons: a. The turbine nozzle ring works under high temperature for a long time, the blades deform, making the nozzle ring cross-sectional area larger, the rotor speed and boost pressure drop; b. Due to turbocharger bearing wear, the rotor blades rub against the casing, or foreign objects are stuck, causing the rotor speed to drop and pressure to drop.

-

Diagnosis and Handling: After parts of the turbocharger fail or deform, abnormal noises will appear during operation. As long as you observe and listen carefully, it is not difficult to find whether the turbocharger has operating faults. According to the inspection results, overhaul or replace the turbocharger assembly.

(9) Sensor Failure

For electronically controlled diesel engines, when the boost pressure sensor fails or is damaged, and the electronic control unit ECU detects fault information, it will compare it with the preset value. If the two do not match, the ECU stores the fault code, lights up the fault light, and issues instructions to make the diesel engine enter the failure control mode (reducing fuel volume, reducing speed).

-

Fault Handling: Use a fault diagnosis instrument to detect the fault code and repair it accordingly.

8.1.4 Excessive Boost Pressure

The main reasons for the rise in boost pressure are as follows.

(1) Fuel System Fault

Due to fuel supply system faults, such as fuel injector filtration, excessive after-burning period causing severe after-burning, increasing exhaust energy, the boost pressure rises as the turbine speed increases. This will lead to excessively high exhaust temperature, the exhaust pipe and turbine casing may turn red, and the rotor is prone to overspeeding. This phenomenon is extremely detrimental to the working of the turbocharger and should be eliminated in time.

(2) Valve Mechanism Fault

Exhaust valve leakage or valve timing mismatch causes turbine speed and boost pressure to rise. Check the valve and readjust the valve timing at this time.

(3) Turbocharger Pressure Regulation Fault

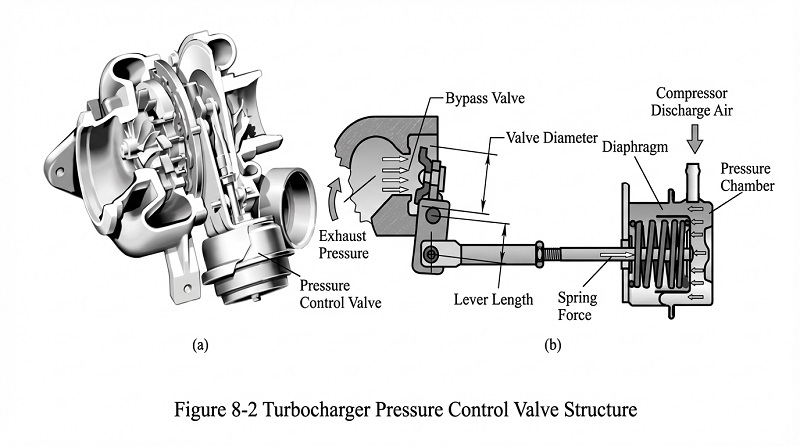

The pressure regulating valve of the turbocharger (Figure 8-2) fails and cannot pass the excess exhaust gas, causing the boost pressure to rise. At this time, the pressure regulating valve should be repaired.

(4) Nozzle Ring Fault

Deformation of the nozzle ring or carbon deposits lead to a reduction in its flow cross-sectional area, causing the boost pressure to rise. Carbon deposits should be removed when there are many.

8.1.5 Abnormal Noise in Turbocharger

Turbocharger blade damage or too small clearance between the rotor blades and the casing, bearing and thrust plate wear seriously, excessive rotor axial play causes the outer edge of the impeller to collide with the casing, or dry friction of moving parts such as bearings and seal rings will all cause abnormal noise. Blade deformation or shaft deflection causing dynamic balance damage, especially severe collision and deformation of the compressor impeller due to foreign object entry, will destroy normal passage and emit high-frequency screaming sounds under the friction of high-speed airflow.

-

Fault Handling: At this time, the turbocharger should be disassembled, and all parts of the turbocharger (including the turbine blades inside) should be cleaned and maintained. If complete repair cannot be grasped, the rotating shaft assembly with blades or the turbocharger assembly should be replaced.

8.1.6 Turbocharger Overheating

Turbocharger overheating includes abnormal phenomena such as excessive intake fuel gas temperature, excessive oil return temperature, and excessive coolant temperature.

(1) Excessive Fuel Gas Temperature

Excessive fuel temperature will cause damage to the turbine blades and casing, and burning of parts such as nozzle rings. The main reasons for excessive fuel temperature are: poor atomizer atomization, excessively rich combustible mixture, excessively small fuel injection advance angle, excessive delay of combustion process caused by excessively long after-burning period (severe after-burning phenomenon).

(2) Exhaust Brake Valve Fault

Exhaust brake valve failure (the butterfly valve is closed during the operation of the diesel engine); excessive exhaust back pressure; turbocharger pressure drops, air volume entering the combustion chamber decreases; engine oil leakage, etc.

(3) Excessive Oil Return Temperature

The oil return temperature is generally lower than 90~120°C (varies depending on the model). Reasons for excessive temperature: reduced oil volume, oil pressure too low (<0.20MPa); oil leakage in the lubrication system, reducing the oil volume at the bearing; blocked oil return pipe, poor oil return; poor oil heat dissipation, failure of the turbo end sealing device, high-temperature gas entering the oil cavity, causing excessive turbocharger temperature.

(4) Excessive Coolant Temperature

Normal water temperature should be below 90°C. Reduced heat dissipation effect of the heat dissipation device, or blockage of the turbocharger water cavity by scale will cause excessive cooling water temperature.

(5) Insufficient Intake Pressure

Under certain specific conditions, if there is air leakage or blockage in the intake system after the turbocharger compressor resulting in insufficient intake of the diesel engine, it may also lead to abnormal phenomena such as the turbocharger turbine casing being burnt red (the main reason is increased after-burning).

8.1.7 Turbocharger Speed Reduction

The main reasons for the speed reduction of the turbocharger are as follows.

-

Accumulation of carbon deposits and other dirt between the rotor and moving parts increases rotational resistance.

-

The nozzle ring deforms due to high temperature, making the nozzle outlet area increase, and the rotor speed decreases. When the nozzle blades are severely deformed, they rub against or bite the turbine blades, causing the rotor to stop rotating.

-

Bearing damage causes the rotating shaft to get stuck.

-

Leakage in the diesel engine exhaust system reduces the gas entering the turbine.

8.1.8 Oil Leaking from Compressor Casing or Turbine Casing

The main reasons causing the turbocharger compressor casing or turbine casing to spray oil outwards are as follows.

-

If the turbocharger is internally supplied with oil, check whether the oil sump level has dropped. If the oil level has not dropped, it indicates that the engine oil sprayed from the diesel engine cylinder has entered the turbine and turned into oil mist spraying out from the air window after condensation. If the oil sump liquid level drops, it indicates that the oil seal is damaged.

-

If the turbocharger is externally supplied with oil, check whether the oil seal of the turbocharger is intact. If it is intact, it is caused by oil channeling in the diesel engine cylinder. In addition, blockage of the turbocharger oil return pipe will also cause engine oil to spray out from both ends of the turbocharger.

Warm Reminder: Some fault phenomena appearing in the turbocharger, their true causes may not be in the turbocharger itself, but derived from other faults. Therefore, when the turbocharger shows mechanical faults (such as abnormal noise, impeller damage, etc.) or fault phenomena other than mechanical faults, mostly the causes are created by other parts of the diesel engine. Therefore, when the turbocharging system shows certain fault phenomena, in addition to conducting necessary testing on the turbocharger, careful and detailed inspection should be carried out on other parts of the diesel engine.

Related products

Language

Language